- Fully automatic ring wrapping machine

- Intuitive touch-screen control panel

- Adjustable number of reinforcement laps

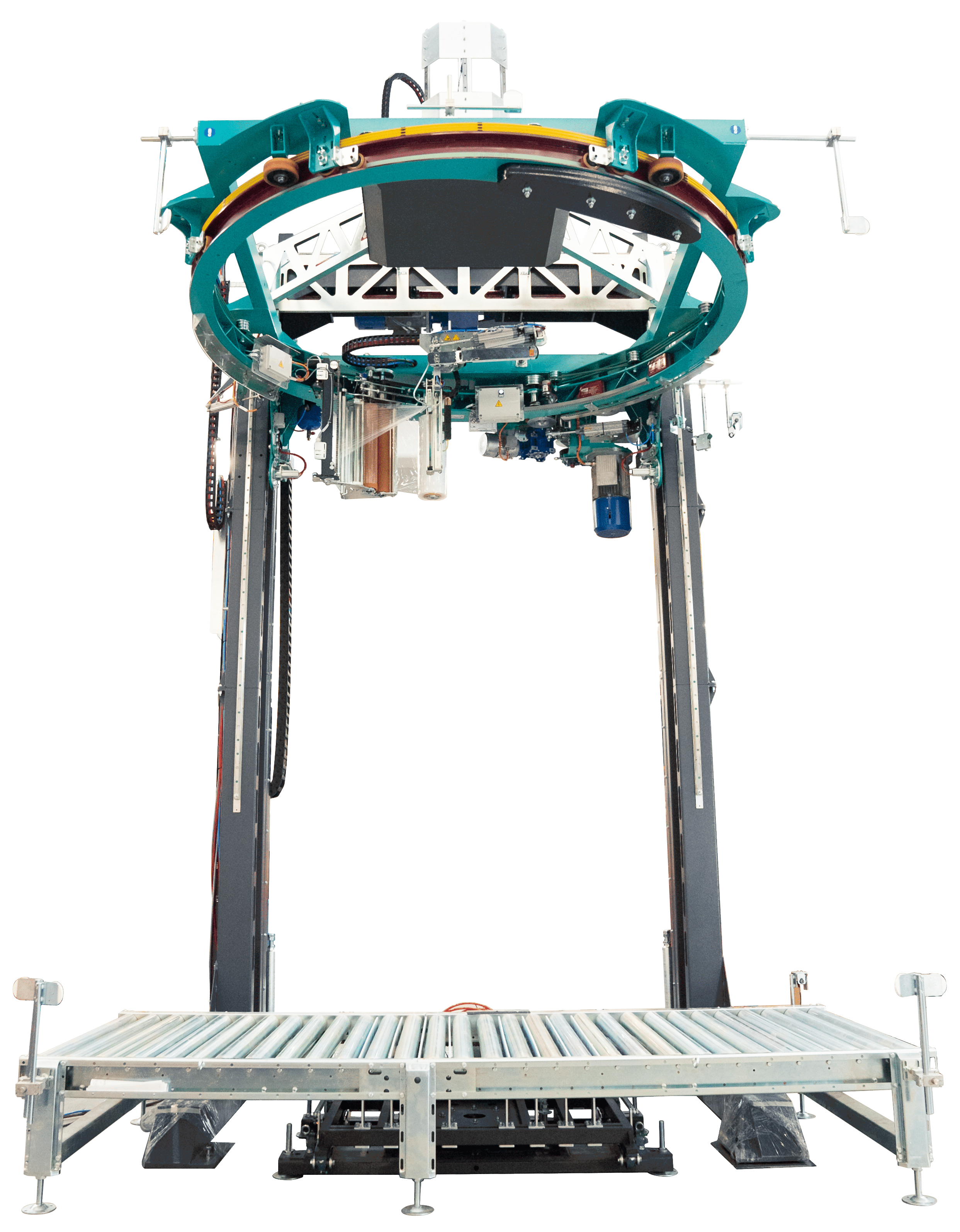

- Input/output roller conveyor

- Automatic pallet height detection

- Maximum arm rotation speed 70rpm

- CE safety protections

- Protective fence with security gate

- Adjustable carriage speed up/down

- Soft start to avoid load dump

- Reinforcement laps at specific points

- Adjustable film tension from control panel

- Start/finish packing at specific height

- Pallet elevator for better wrapping

- Film consumption reading (PRS, PS)

- Possibility to use jumbo reels (40kg)

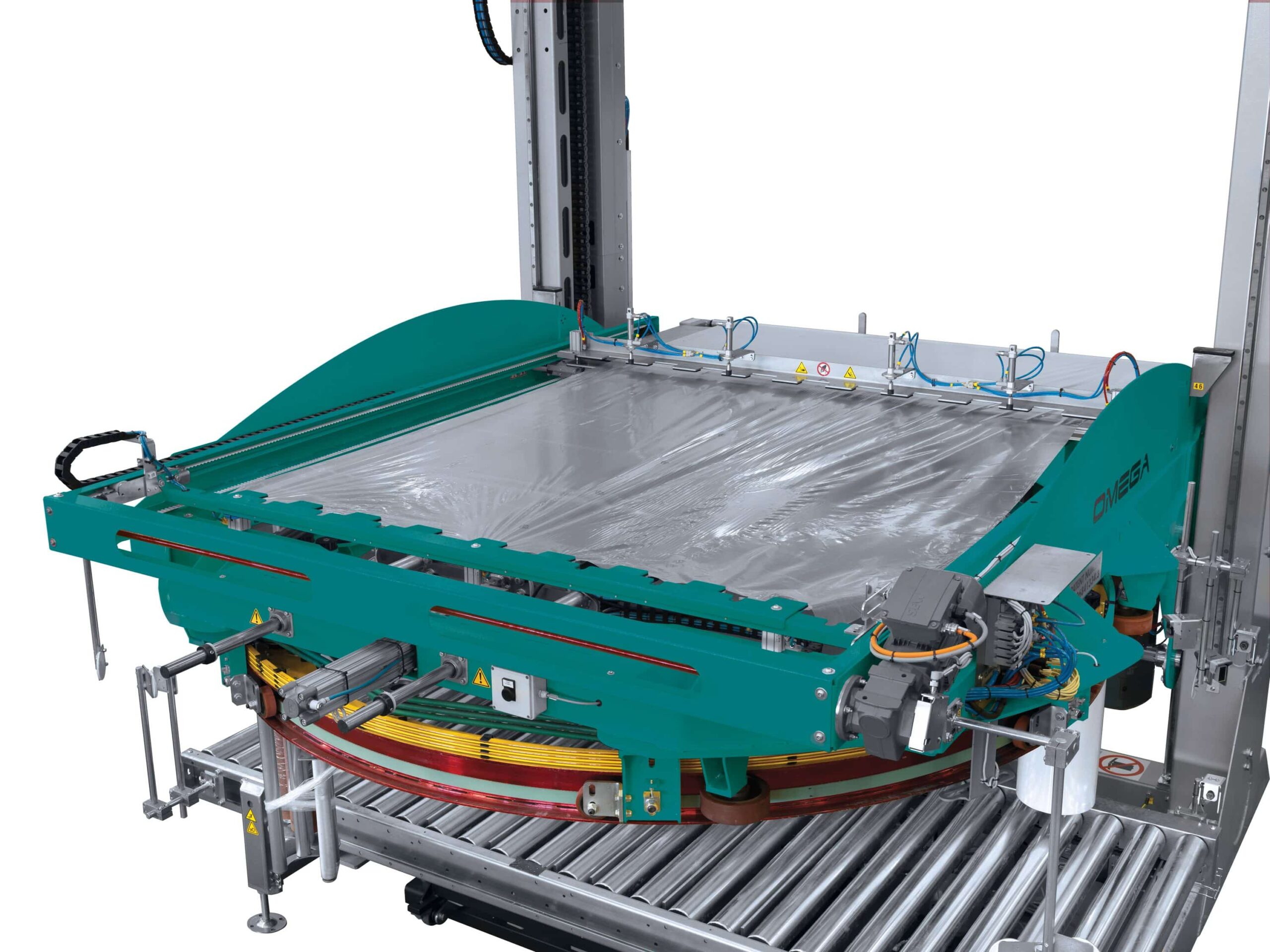

- Pallet cover function (waterproofing)

- Automatic edgebander

- 99 different programs to save

- Integrated clamp and clean cut unit

- Automatic cord system

- Film sealing clamp cutting system

- Rope system to stabilize load

- Limited stroke pallet presser

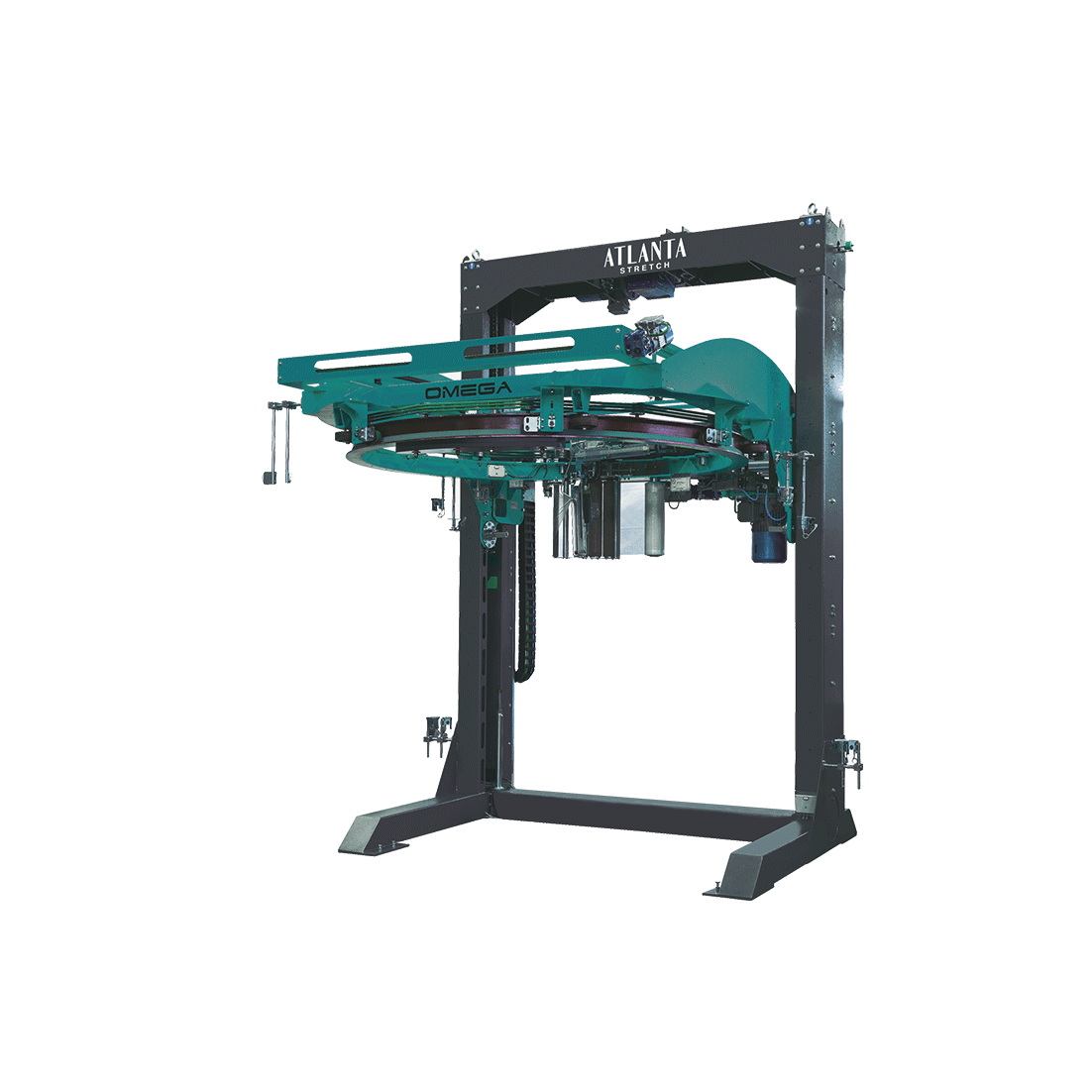

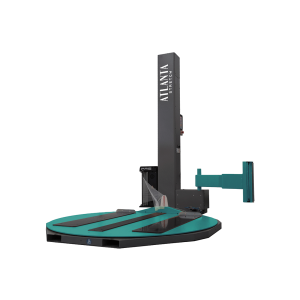

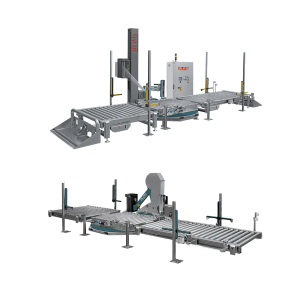

Omega ring wrapper

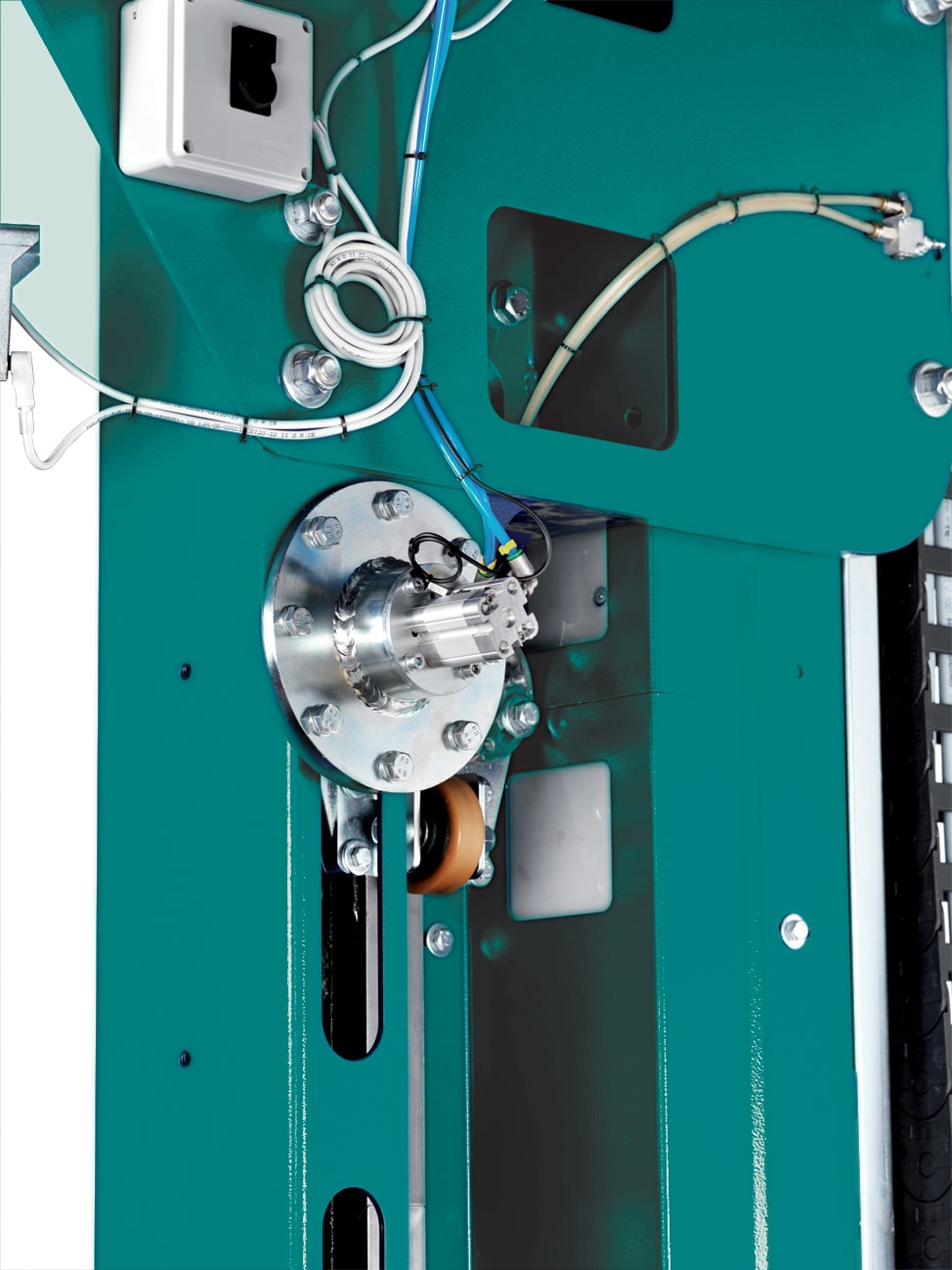

Omega is designed for the highest packing rates on the market. With more than 100 pallets / hour, this is a machine that meets the highest standards on the market. Regarding construction, the ring is supported by two columns that ensure the highest performance. It is in the ring where Omega differs from the rest. While the rest of the machines on the market have brushes and electronic elements, Omega dispenses with all of this to reduce maintenance costs, while maintaining the expected performance.

Ring wrapper – maximum performance

The equipment required for an end of line with an Omega must be of a very high standard in every way. The touch control desk allows management of all elements, and all this is installed with a metal cage that protects other operators from the movements of the machine.

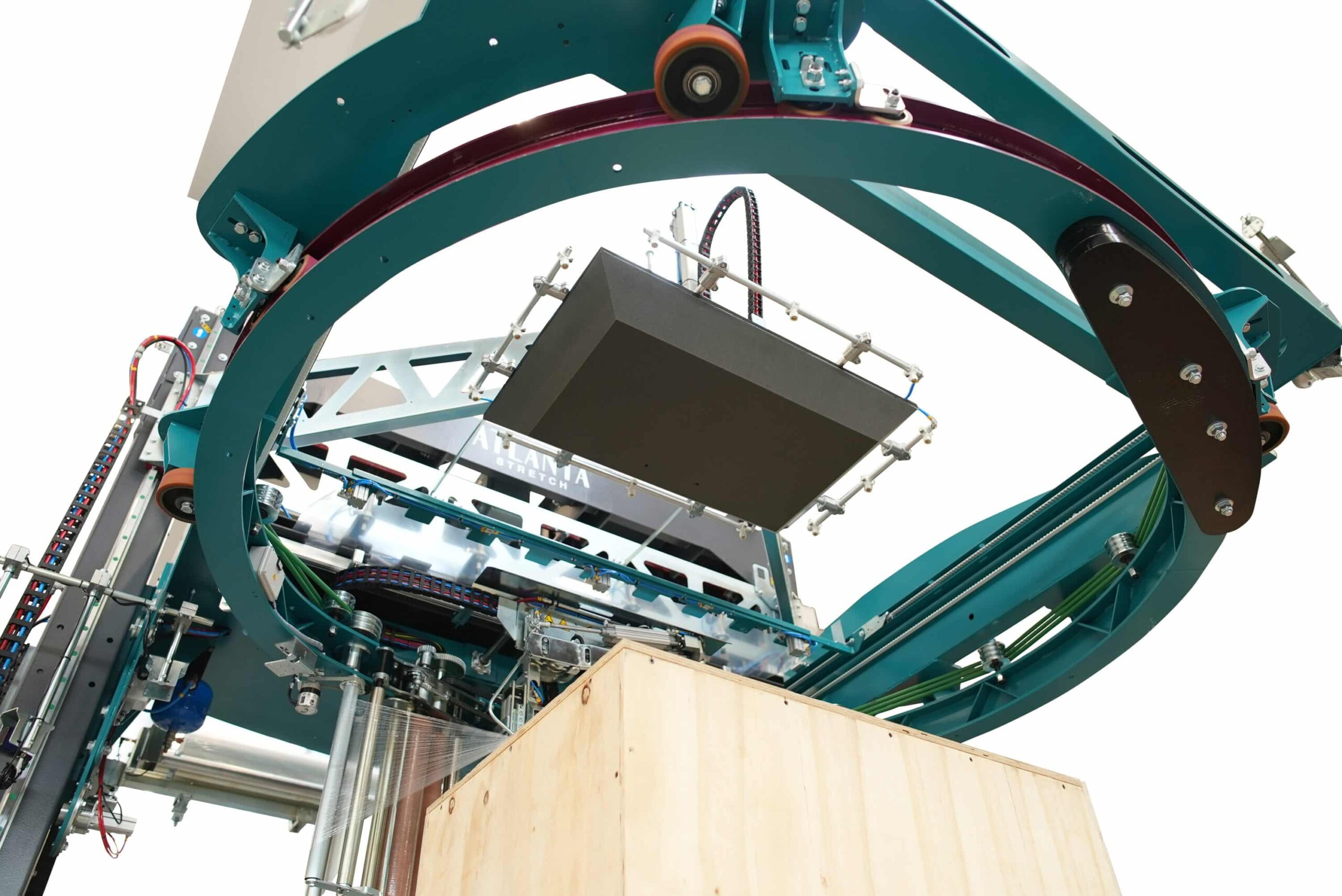

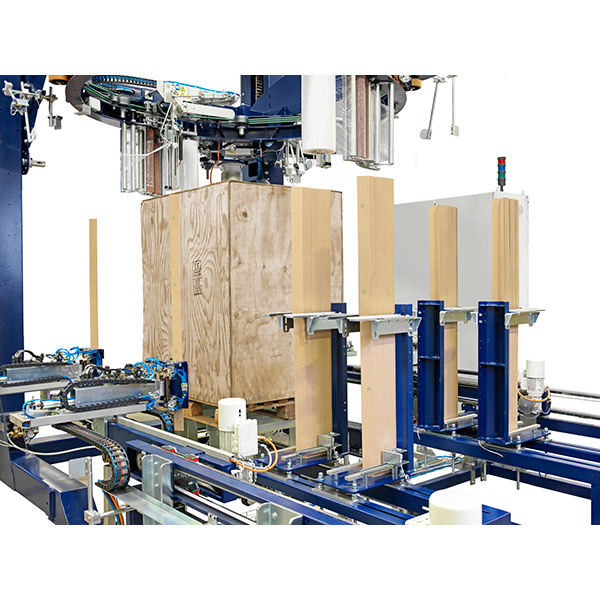

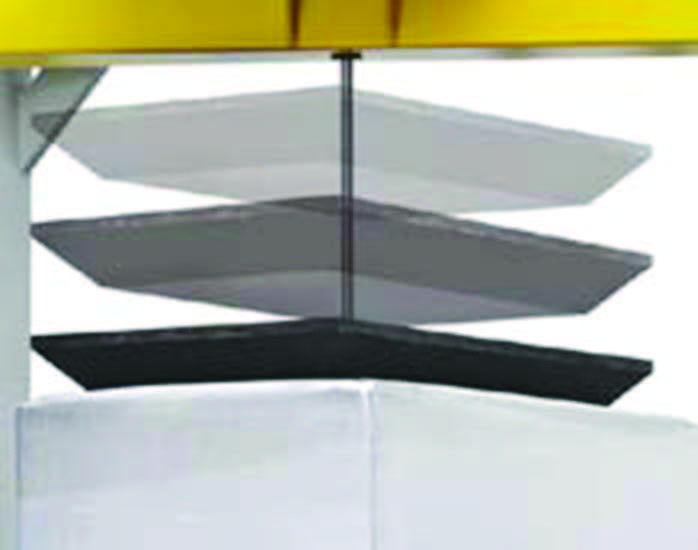

The performance of the Omega can be increased with the addition of a second spool, making it the Double model. More film, more speed, more efficiency. In addition to this, you can also have a series of optional items that will give more versatility to the machine, from the automatic incorporation of corner pieces to a grip and cut system that allows the machine to weld film at the end of an application.

Optional items

Among the different variations of the machine, you can have:

- Conveyor at different height

- Circular upper clamp

- Rectangular upper clamp

- ROPE creation system

- Welding system (grip and cut)

- Automatic corner piece installation

- Optional second coil (Omega Double)

Español

Español Français

Français